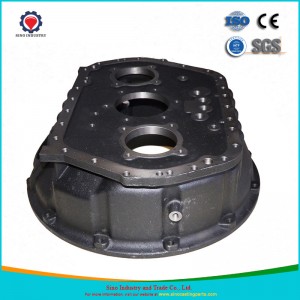

China Custom Casting Grey Iron Parts OEM/ODM Service for Auto/Car/Truck/Automotive/Automobile Accessories

Basic Info.

| Item | Auto/Machinery Parts |

| Surface Treatment | Shot blasting/Polishing/Painting/Powder coating/Anodizing/Zinc plating/Nickel plating/blacking, etc. |

| Surface Roughness | Ra0.05∼Ra50, depends on Customer’s Requirements |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting tolerance | CT5-CT8 |

| Casting blank size | 2mm-1500mm or according to customer's requirement |

| Casting blank weight | 0.05kg-3000kg |

| Coating | Electrophoresis Coating |

| Machining | Lathing/Milling/Turning/Boring/Drillig/Tapping/Grinding, etc |

| Machining tolerance | 0.01mm |

| Design software/ formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works/CAXA/Rhino/CATIA/SIMIO/ALIAS/ARENA/Unigraphics, etc |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Application | Automobile, Car, Heavy Truck, Light Truck, Commercial Vehicle , Forklift, Construction Machinery/Truck/Vehicle, Farm Vehicle/Machinery/Truck, Agriculture Machinery/Truck/Vehicle, Mining Machinery, Marine Hardware, Train, Railway, Petroleum Machinery, Engineering Machinery, Shipbuilding, Power Equipment, etc. |

| Package | Bubble plastic bag/polybag/pallet/wooden case, etc. |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| Annual Supply | 1000000 Pieces |

| Sample | Available |

| OEM/ODM service | Available |

Product Description

| Custom Die Casting Parts | |

| Mold Material | SKD61, H13 |

| Mold Cavity | Single or multiple |

| Mold Life Time | 50K times |

| Product Material | 1) Aluminum alloy ADC10, ADC12, A360, A380, A413, A356

2) Zinc alloy 3#, 5#, 8# |

| Surface Treatment | 1) Polishing, Sandblasting, Painting, Powder coating, Galvanizing, Chrome plating, Spray coating, Anodizing

2) Polishing+ zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing →Shipping |

| Size | According to customers' drawings or samples |

| Casting Machine | Die casting machine 88 ton/280 ton/400 ton/500 ton/800 ton/1250 ton |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001:2015 |

| Payment Term | T/T,L/C, Western union |

| QC system | 100% inspection before package or one by one |

| Monthly capacity | 50,000pcs |

| Lead time | 10~25working days according on quantity |

| Application | 1) Led light housing & Led Heatsink

2) Auto & Motorcycle & Bicycle parts 3) Furniture accessories 4) Solar energy 5) Pump housing 6) Mechanical parts 7) Diecasting kitchen utensils |

Gray iron vacuum casting from China foundry with OEM custom services.

Castings due to the technique that is used to create these metal parts. The process begins by placing a two-piece mold in a vacuum castings due to the technique that is used to create these metal parts. The process begins by placing a two-piece mold in a vacuum chamber. The vacuum then draws the molten metal into the mold. Finally, the casting is solidified in an oven and the mold is removed in order to release the final castings.

Vacuum Casting Materials:

Carbon Steel: Low Carbon Steel, Medium Carbon Steel and High Carbon Steel from AISI 1020 to AISI 1060.

Cast Steel Alloys. ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrM0... etc on request.

Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L and other stainless steel grade.

Brass & Copper.

Other Materials and Standards on request.

Lost Foam Casting Foundry from China

Raw Materials Available for Lost Foam Casting (LFC):

• Carbon Steel: Low carbon, medium carbon and high carbon steel from AISI 1020 to AISI 1060.

• Cast Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L and other stainless steel grade.

• Brass & Copper.

• Other Materials and Standards on request

Capabilities of Lost Foam Casting

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.05 kg - 3000 kg

• Annual Capacity: 110,000 tons

• Tolerances: On Request.

Main Production Procedure

During lost foam casting process, the sand is not bonded and a foam pattern is used to form the shape of the desired metal parts. The foam pattern is "invested" into the sand at the Fill & Compact process station allowing the sand into all voids and supporting the foam patterns external form. The sand is introduced into the flask containing the casting cluster and compacted to ensure all voids and sapes are supported.

• Mold foam pattern making.

• Age pattern to allow dimensional shrinkage.

• Assemble pattern into a tree

• Build cluster (multiple patterns per cluster).

• Coat cluster.

• Foam pattern coating.

• Compact cluster in flask.

• Pour molten metal.

• Extract cluster from flasks.

Inspecting Lost Foam Castings

• Spectrographic and manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell and Vickers hardness inspection

• Mechanical property analysis

• Low and normal temperature impact testing

• Cleanliness inspection

• UT, MT and RT inspection

Post-Casting Process

• Deburring & Cleaning

• Shot Blasting / Sand Peening

• Heat Treatment: Normalization, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Andonizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec.

• Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding.

Why Choose us for Custom Lost Foam Casting Parts?

• Greater design freedom in the construction of cast parts

• Small quantity is possible due to the layered structure of the pattern.

• Lower need for secondary machining with near net shape.

• High flexibility by short start up lead time.

• Longer EPS mould span life, thus lower average tool costs

General Commerial Terms

• Main workflow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Leadtime: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

What type of castings can we deal with?

| Machine | Die casting machine 88 ton/280 ton/400 ton/500 ton/800 ton/1250 ton |

| Material | Aluminum alloy ADC10 . ADC12 . A 360 . A380 .zinc alloy |

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → |

| Drilling and threading → CNC Machining → Polishing → Surface treatment | |

| → Assembly → Quality inspection → Packing →Shipping | |

| Surface treatment | Polishing, Sandblasting, Painting, Powder coating, Galvanizing, Chrome plating,Spray coating, |

| Application | Led light housing & Led Heatsink |

| Auto & motocyle & bicycle parts | |

| Furniture accessories | |

| Power tool housing | |

| Pump housing | |

| Mechanical parts | |

| Diecasting kitchen utensils | |

| Drawing Format | Auto CAD,CAD, PDF,3D, SLDPRT |

| ISO Cetificate | ISO9001-2008, Rohs |

| Payment term | T/T, L/C, Western union |

| QC system | 100% inspection before package or one by one |

| Lead time | 30~45 days for mass production |

| Annual capacity | 1000,000pcs |

| Our advantage | More than 40 years of experience in casting industry |

| With talented and experienced engineers |

Main castings

grey iron accessory, iron accessory, casting factory, casting foundry, casting manufacturer, casting manufactory, forging factory, forging foundry, forging manufacturer, forging manufactory, forging accessory, metal accessory, hardware accessory, casting, castings, forging, stamping, machining, cnc machining, machining accessory, cnc machining accessory, machining foundry, professional casting, custom casting, precision machining, sand casting, die casting, lost wax casting, investment casting, vacuum casting, gravity casting, nonstandard accessory, precision casting, metal casting, cast metal accessory, cnc accessory, machinery accessory, machine accessory, mechanical accessory, auto accessory, spare accessory, auto spare accessory, car spare accessory, truck spare accessory, lorry spare accessory, automotive spare accessory, automobile spare accessory, automotive accessory, automobile accessory, car accessory, truck accessory, lorry accessory, heavy truck accessory, heavy-duty truck accessory, transport truck accessory, heavy transport vehicle accessory, vehicle accessory, forklift accessory, farm vehicle accessory, farm truck accessory, farm machinery accessory, farm machine accessory, agricultural vehicle accessory, agriculture vehicle accessory, agricultural truck accessory, agriculture truck accessory, agricultural machinery accessory, agriculture machinery accessory, agricultural machine accessory, agriculture machine accessory, combine harvester accessory, tractor accessory, trailer accessory, mining equipment accessory, mining machinery accessory, mining machine accessory, mining truck accessory, mining vehicle accessory, industrial accessory, industry accessory, equipment accessory, device accessory, facility accessory, engine accessory, motor accessory, pump accessory, pump body, pump shell, pump housing, pump casing, pump cover, water pump, impeller, pump impeller, hydraulic pump accessory, pump spare accessory, water pump accessory, hydraulic spare accessory, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction, fuel pump, diesel water pump, vacuum pump, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, valve accessory, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox accessory, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder

cast iron, iron casting, iron cast accessory, casting accessory, sand cast accessory, sand casting accessory, cast machine accessory, cast machinery accessory, machine spare accessory, coupling, marine hardware, precision accessory, high performance accessory, high quality accessory, truck bracket, lorry bracket, engine bracket, motor bracket, steering gear bracket, leaf spring bracket, balanced suspension, suspension system, suspension arm, steering knuckle, vehicle bracket, bumper bracket, exhaust pipe, exhaust pipe manifold, diesel engine, etc.

FAQ

1. Are you a factory or a trader?

A: We have our own factory (established on 1980) and sales company (Sino Industry and Trade Co., Ltd.)

2. Do you support product customization?

A: Yes, we mainly promote customized processing routes (process customization, material customization, surface treatment customization, etc.). According to your samples or drawings, our professional designers will draw 3D data models for you and make samples!

3. How do you control and ensure product quality?

A: We will prevent beforehand, manage during the event, and guarantee after the event. Confirm with you every detail before quoting. After you order, we will reconfirm all the details again. So we can reduce the losses of time and costs.

We strictly implement the "IATF 16949 Quality Management System" standard in production, and we will send you videos and pictures during the production and shipment process.

4. How can I receive a quotation?

A: Please send us your product drawings or picture information via email, and we will provide you with a product quotation within 2 working days!

5. How do I place an order?

A: Please try to provide the following information:

* Product information: specifications, quantity, expected price

* Delivery requirements

*Payment

* Shipping information: name, detailed shipping address, phone number, shipping requirements (courier, air, or sea).

* If there is a cooperative freight forwarder, please provide the contact information of the freight forwarder.

* Please send us an official purchase order by email. or we can provide proforma invoices for you.

6. How to send the product to me?

A: The transportation way is up to you. We can also recommend more economical transportation for you!

For small batches under 30kg, express delivery (DHL, FedEx, TNT, UPS, EMS, or others) is commonly used.

Orders of 30-500 kg can be airlifted to your designated airport.

For large quantities or large volumes, we often use sea freight.

7. Can you arrange the transportation of the goods for me?

A: Yes, we can send you by sea, air or courier.

8. What is your preferred payment item?

Answer:

1) Samples are paid via Paypal and T/T is 100% paid.

2) Bulk orders: T/T 30% prepaid, the balance should be paid before shipment.

10. Please contact me through my business card for more information.